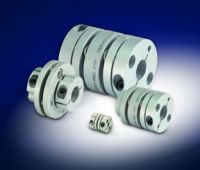

Zero-Max ServoClass Couplings Offer Robust Design Features

Design engineers looking to increase speeds in electronic assembly systems will find ServoClass Couplings from Zero-Max a viable design option. ServoClass Couplings provide high torsional stiffness, zero backlash and low hysteresis to ensure repeatable precise positioning at speeds up to 10,000 rpm. Their robust design ensures precise system operation in automated 24/7 applications. That is especially true where stresses occur at increased speeds in a servo system. Designed with 304 stainless steel disc packs and 7075-T6 aluminum hubs, ServoClass couplings are inherently strong, durable and precisely balanced. To ensure precise alignment of the assembled components, ISO 4762 CL12.9 corrosion resistant socket head cap screws are utilized with a carefully controlled assembly process. (Competitor couplings are assembled utilizing brazing, gluing and otherwise less precise methods with more variability).

"ServoClass couplings are designed to handle the specific sensitivities of servo systems," reports Robert Mainz, Zero-Max sales manager. "The design of the coupling takes into account the mechanical as well as the electrical attributes of the system with the mechanical components keeping up with the electronic commands of the controller. The design specifications of the ServoClass coupling aid in making these two entities work far better together than other couplings when used in servomotor applications." In addition to electronic assembly systems, ServoClass couplings are suitable for all types of automation, packaging and other types of automated assembly including most systems using ball screws and servomotors. ServoClass couplings are available in single and double flex models in inch and metric bore sizes from 0.157 inch (4 mm) to 1.750 inch (45 mm). All models and sizes feature clamp style hubs and operate in temperatures from -22 to +212 degrees F (-30 to +100 degrees C).