An innovative technology for the next generation of high-speed, high power density traction and propulsion systems has been jointly developed by Drive System Design (DSD) and Transense Technologies. David Hind, principal engineer, DSD, presented “Unlocking Powertrain Power Density with Innovative Motor Control,” earlier this year at the CTI USA Symposium 2025 in Novi, MI. The presentation built on initial simulation studies performed in MATLAB Simulink; a software tool used to design and simulate systems before moving to hardware. While simulation trials proved successful, achieving quality experimental results proved far more challenging. Hind examined these challenges and potential solutions at CTI.

Motor solutions are the lifeblood of many applications, powering the precise movements and operations that keep automated systems running smoothly. While each system presents unique demands, the wide variety of motor types available ensures there is an option suitable for each specific need. It is vital to understand the pitfalls of choosing an inappropriate motor, given the countless motor types, brands and sizes.

.

As industries adopt more automation, the demand for reliable and efficient pneumatic systems, which power everything from robotic arms to air-powered tools, continues to rise. However, despite their widespread

use, these systems often suffer from hidden inefficiencies. Here, Chris Johnson, managing director at SMB Bearings—Oxfordshire, U.K.) explores how an overlooked component, industrial bearings, can improve the

efficiency of pneumatic technologies.

The SKF Lincoln SL-6 metering device is a single-line automatic lubrication system injector. Its proven design is thoroughly updated to meet new demands on maintainability, leakage-protection and long-lasting performance even with harsh extreme pressure greases. Today’s manufacturing environment demands less maintenance time, higher productivity demands and little to no tolerance for unplanned production stops.

.

C-COM Satellite Systems, a manufacturer of mobile satellite antennas, has integrated several models of Bodine Electric motors across a variety of platforms. These motors are primarily used to drive the Azimuth

and Elevation axes on their Fly-Away (portable) and Drive-Away (vehiclemounted) systems.

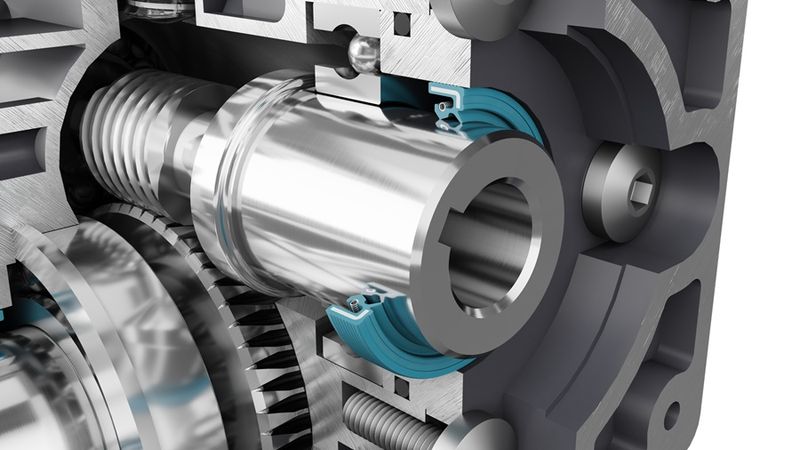

The spectrum of machinery and equipment used in industrial automation includes everything from electric motors to robotics and each has its own unique attributes and sealing requirements. David Kaley, Trelleborg global segment manager for industrial automation, shares his expertise on speed reducers covering what they are, how they work and key considerations for correct sealing in this article.

Since taking over as CEO of Solve Industrial Motion Group in June 2024, Ernie Lauber has focused on continuous improvement, predictive maintenance and growing the legacy brands within Solve.

Combining brands such as IPTCI, MasterDrive, PTI and TRITAN together with the LMS, SST, SPB-USA and USA Roller product lines, Solve Industrial Motion Group is a provider of high-quality metric and American Standard power transmission components and industrial-grade bearings.

Closed Loop control systems can handle a wide range of motions with a wide range of loads if the control system and mechanics are properly designed for the task. A couple of the more difficult combinations to design for are high inertial mismatches and backlash with hard gearing. The question is not just how to make the system stable, but rather how to also get the desired performance.

The Simplicity self-lubricating linear plain bearings are built to last, and they will often out-perform and last longer than a traditional linear ball bearing. Called the “little red bearing” by loyal customers, they have been a popular replacement for failing ball bearings. Simplicity plain bearings will not catastrophically fail.

The difference between a smooth-running drive and constant headaches? The right timing belt and pulley plus a whole lot more. Discover what works, what doesn’t, and put your design skills to the test—engineer your best system yet!

Discover how Regal Rexnord’s Bauer™ PMSM gear motor helped a transportation company streamline inventory, cut energy use, and save $80,000 annually. Learn how this scalable solution delivers financial, operational, and sustainability gains across facilities.

Design engineers are always on the lookout for efficient and reliable application solutions. While standard products often suffice, some challenges demand a custom approach. Custom machine couplings, critical for torque transmission between a machine's driving and driven components, require careful consideration of specific requirements to guarantee optimal performance and unwavering reliability.

Precision elastomer insert couplings offer vibration damping, easy installation, zero backlash transmission, and electrical isolation. Fitting a wide variety of drive applications including lift systems, conveyors, pumps, linear actuators, and high performance general power transmission.

Forest City Gear manufactures extremely high-precision gears made for the most advanced robotics, right in Roscoe, IL. This family-owned team of gearheads specialize in high-precision gears engineered to handle the most demanding robotic applications—on Earth, and way beyond.

Dec 12, 2025

The team at David Brown Santasalo (DBS Canada) recently carried out the successful delivery of a time-sensitive and complex service project for a valued, long-standing customer in the mining industry. This project supported operations at a gold mine located in one of the most remote regions of northern Canada, just below the Arctic Circle.

Mar 3, 2026 - Mar 7, 2026

CONEXPO-CON/AGG brings the entire construction ecosystem together in one place, giving over 139,000 construction professionals access to equipment manufacturers, technology innovators, workforce trailblazers and the thought leaders who are changing the world through infrastructure, innovation and leadership.

Jan 20, 2026 - Jan 22, 2026

Feb 10, 2026 - Feb 12, 2026

Current Issue

Current Issue

Archives

Subscribe

Buyer's Guide

Accessories Actuators Adjustable Speed Drives Bearings Belting & Belt Drives Brakes Chain & Chain Drives Clutches Controls Couplings & U-Joints Fluid Power Gear Drives Gear Manufacturing Services Gears Industrial Hardware and Machine Parts Linear Motion Devices Lubrication Motors Resources Seals Sensors Services SoftwareThe Power Transmission Engineering Buyers Guide is your complete directory of suppliers of mechanical power transmission components, including great companies like these.

VIEW ALL